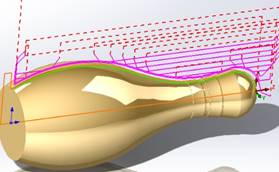

Please find the file: bowling-pin-Simon.sldprt in the Z drive: Z:/manf2000/manf2000-labs/bowling pin folder. Do not open it from the Z:drive! Copy it to your desktop, or somewhere on your computer and work on it there. We will complete this bowling pin together in class. Please take notes and be sure to work in groups to assist one another. After completing the in-class tutorial please design a simple part that is no longer than 3” in length, using 1.0” diameter 6061-T6 aluminum stock. Typically, chess pieces or some other small decorative part. Nothing that at all resembles a bullet will be accepted. Baseball bats will, when scaled become too narrow in diameter. The part will be graded on the following criteria: · Timeliness: completed by due date · Machining surfaces: neat and clean, no sanding or scotch-brite. The machining marks must be left on the part. · Part thickness and consistency of thickness as well as finish and machine marks. I’ll specifically be looking for chatter. BE SURE to remove the tool nose radius in the tool table before

cutting your part!!! Since we are using constant velocity machines our spindle rpm’s will be determined by surface speed (SFM) settings. In the Operation F/S tab the default setting is Library. Pull down the menu and change it to Operation. We have had good luck with the following settings: Surface Speed: 300SFM Feed rates: FPR For Roughing: 0.015in/rev For Finish pass: 0.0015in/rev |

||

|

|