|

Wentworth Institute of Technology Mechanical Engineering and Technology Department |

||

|

|

|

|

|

Course |

MANF2000 Computer Aided Manufacturing |

|

|

|

|

|

|

Instructor |

Peter Rourke, CMfgE |

|

|

|

|

|

|

Semester |

Spring, 2020 2 hours lecture 2 hours laboratory 3 credits |

|

|

|

|

|

|

Catalog |

Students will utilize PC based industrial CAM software and Computer Numerical Control machines to produce machine tool programs and parts. |

|

|

|

|

|

|

Prerequisite |

MANF1000 Manufacturing Processes |

|

|

|

|

|

|

Required |

|

Kalpakjian, Serope and Schmid, Steven R., Manufacturing Engineering and Technology, 7th ed., Pearson, Boston, 2014, ISBN-13: 978-0-13-312874-1 |

|

|

|

|

|

Suggested |

|

Machinery's

Handbook (28th Edition) Electronic |

|

|

|

|

|

Course |

Students will become competent in applying the design parameters involved in Computer Numerically Controlled (CNC) material removal processes including milling and turning, as well as in rapid prototyping additive processes. |

|

|

|

|

|

|

Objectives |

To exhibit proficiency in the

fabrication of components using Computer Numerical Control (CNC) equipment,

Rapid Prototyping (RP) systems, and matching design criteria to both CAM and

RP process capability, each student will:

|

|

|

|

|

|

|

Grading |

· Laboratories: 30% · Attendance / group work: 25% · Quizzes and assignments: 30% · Final exam: 15% |

|

|

Topic |

Topic |

Assignment |

Laboratory |

|

|

|

|

|

|

1 |

Machining

Processes: Milling |

Chapter 24 (review) |

Technology Database |

|

|

|

|

|

|

2 |

Surface Technology |

Chapters 33,34 |

|

|

|

|

|

|

|

3 |

Fundamentals of Machining |

Chapter 21 |

|

|

|

|

|

|

|

4 |

Tool Life: Wear and Failure |

Chapter 21 (cont.) |

Plasma Torch 2-axis Laboratory |

|

|

|

|

|

|

5 |

Cutting Tool Materials-Fluids |

Chapter 22 |

|

|

|

|

|

|

|

6 |

Machining Centers |

Chapter 25 |

|

|

|

|

|

|

|

7 |

Automation and Operations |

Chapter 37 |

Project |

|

|

|

|

|

|

8 |

Plastics Manufacturing |

Chapter 19 |

Semester Project |

|

|

|

|

|

|

9 |

Semester Review |

SolidWorks Certification Exam |

CSWP-CAM |

|

Materials

About the Textbook: The textbook for this course is Kalpakjian, Serope and Schmid, Steven R., Manufacturing Engineering and Technology,

7th ed., Pearson, Boston, 2014,

ISBN-13: 978-0-13-312874-1. You

must purchase the text. There is a

copy on reserve in the library until you do. Course

Notes: |

||

|

|

||

|

1.

Please do not ask me to re-open any quiz for

any reason. 2.

All laboratory

work and projects become property of Wentworth Institute of Technology. They will not be returned to you. If you want a part or project for yourself,

you must make multiple copies. I get

the one you wish to submit for a grade.

No exceptions. 3.

Any machined part

finished with scotch bright, sandpaper, or polish will automatically receive

a score reduction of 50 points. 4.

Please have on

your laptop the most current image provided by DTS. The software we will be

using includes: ·

SolidWorks ·

Adobe Acrobat

(reader) ·

MS Office 5.

If you arrive

to class or lab and do not see the electronic attendance sheet I use, it

means you arrived late. You will be

marked absent unless you stay at the end of the session and have me change

the spreadsheet to mark you as late, rather than absent. 6.

Completed quizzes can be reviewed after they can be taken by

clicking on the numerical score for each quiz under "my grades" in

blackboard. 7.

If you ask me

to help you with CAMWorks you must have a mouse attached to your computer. 8.

The final exam

consists of two parts: one is the on-line exam and the other is a display of

all your work from the semester to be set out in the lab. |

||

|

|

||

|

Laboratory

Notes: |

||

|

|

||

|

1.

Please have

your safety glasses with you at all times: lecture and lab. Each time I lend

you a pair, or ask you to put them on, reduces your course participation

grade. I will not be the “safety

glasses cop”: you will simply receive a lower lab grade. 2.

Always have at

the ready your "Best-Practices" notebook. I recommend a cheapy

spiral graph paper notebook from Staples ($0.99) 3.

Cell phone use

is not permitted in the laboratory.

Please put your cellphone in your book bag. If you must use the phone for any reason,

please tell me so that you may be excused from the lab. 4.

There must be 2

members of a group present when you are running any equipment. Please do not

ask me to gain entry to a lab unless there are 2 of you. Please put effort into making your group a

team. This is part of the “group work:

15%” grade from above. 5.

You are

responsible for a thorough clean-up after using any equipment. 6.

There are three

“shut-down” emergency buttons on the walls of the lab. If you see someone in trouble on a machine

hit the EMERGENCY STOP button. This

will stop the spindles from turning.

They are a no-harm-no-foul button. 7.

The Tool Tables

for the ProtoTRAK mills are saved on each machine. If for any reason you change a tool let me

or Ryan know so that you can correct the tool table. 8.

https://www.lincolnelectric.com/assets/servicenavigator-public/lincoln3/im10197.pdf 9.

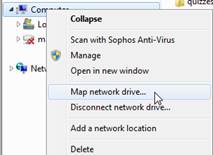

To view quiz

results, available after the due date and time: |

||

|

|

||

|

Learning and

Competency Objectives (a) an ability to apply knowledge of mathematics, science, and engineering (b) an ability to design and conduct experiments, as well as to analyze and interpret data (c) an ability to design a system, component, or process to meet desired needs within realistic constraints such as economic, environmental, social, political, ethical, health and safety, manufacturability, and sustainability (d) an ability to function on multidisciplinary teams (e) an ability to identify, formulate, and solve engineering problems (f) an understanding of professional and ethical responsibility (g) an ability to communicate effectively (h) the broad education necessary to understand the impact of engineering solutions in a global, economic, environmental, and societal context (i) a recognition of the need for, and an ability to engage in life-long learning (j) a knowledge of contemporary issues (k) an ability to use the techniques, skills, and modern engineering tools necessary for engineering Students will be given project parts

to fabricate, and sophisticated CNC tools, equipment and software necessary

to complete the work. Using these

modern engineering tools students will demonstrate their ability to design a

process proving the manufacturability of the component. Results will be critiqued and displayed at

the front of the laboratory at the end of the semester. |

||

|

DISABILITY SERVICES STATEMENT: Any student who thinks s/he may require a disability-related

accommodation for this course should contact Disability Services in the

Counseling Center privately to discuss your specific needs. Disability Services coordinates reasonable

accommodations for students with documented disabilities. They are located in Watson Hall 003 (the

Counseling Center) and can be contacted at 617-989-4390 or counseling@wit.edu. For

more information on acceptable documentation and the Disability Services

process, visit the Disability Services website at www.wit.edu/disabilityservices ACADEMIC HONESTY

POLICY: Students at Wentworth are expected to be honest and forthright

in their academic endeavors. Academic dishonesty includes cheating, inventing

false information or citations, plagiarism, tampering with computers,

destroying other people’s studio property, or academic misconduct. COLLEGE OF THE

FENWAY STUDENTS: If you are enrolled in this course

through COF Cross Registration, notify your course instructor. Please provide

her/him with your email address to be sure that you receive course

information in a timely way. You should also discuss how to access online

applications that might be used in the course. Please note that cross

registered students who wish to drop or withdraw from this course must

complete the necessary paperwork according to the Wentworth calendar. |

|

LAB GRADING CRITERIA It is my hope that you will find the

laboratory projects beneficial in your academic and professional

efforts. Much of the grade for the

course is taken from these activities.

It is my experience that students fall somewhere within three

categories in the laboratory:

Daily

lab grades are recorded. With the

exception of one or two lab periods designated as design sessions (I will be

clear when they are coming up) your lab grade is determined by the amount of

time you spend cutting and fabricating.

We can do design work anywhere and at any time, however our time on

the lab equipment is limited and needs to be maximized. Grading guidelines are as follows: · 100-90: All set up ready to go: setup sheets printed, part file on network, spacer heights calculated. Cutting commences within 10 minutes of class beginning. · 90-80: All members present at the equipment station, set up sheets printed, and part file ready to be post-processed and put on the network · 80-70: Last minute tweaking required, part requires last minute post-processing changes, and set up sheets need to be printed, but work commences within 30 minutes of lab start. · 70-50: Cut strategies finalized and cutting commences within an hour of start of class. · 50-0: Not prepared and still designing I will be visiting each group, asking for a set-up sheet. It must include the spacer calculation. When you print them, be sure to print two, as I will be keeping one. Please use the communications tools available to you (Google Docs, Skype, etc.) to do your design work as a team outside of class time. Note that while machining work done outside of class will almost certainly raise your laboratories grade section (30%), the efficient use of your assigned lab time is also important (25%). |

|